Silrec Corporation is a multi-faceted organization, offering a wide range of products and services to the semiconductor and solar industries. The company has a long standing commitment for protecting the environment by recycling scrap silicon obtained from both sources. We continue to establish new relationships within these industries with a dedicated commitment to explore and recycle scrap material for alternative uses.

As a pioneering silicon distributor who specializes in silicon remelt, Silrec is also positioned as a leading silicon supplier representing the top silicon producers in the United States. With the pride of having serviced the silicon industry for over 34 years and building an outstanding reputation in the industry, we are always looking to establish new partnerships. Founded in Silicon Valley, California (San Jose) in 1986, our mission is to provide superior products at competitive prices to the mutual benefit of both buyer and seller.

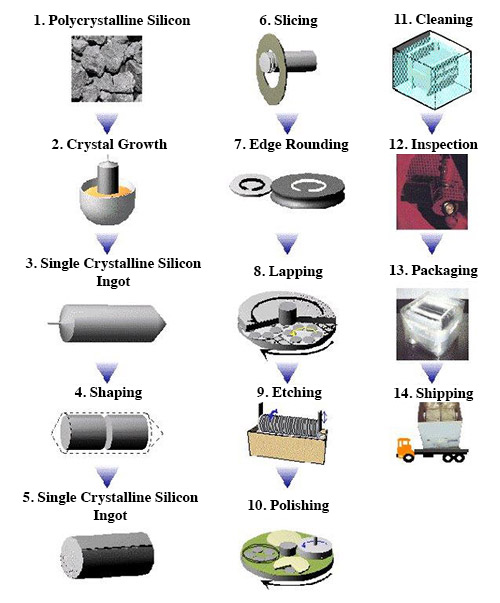

1.) Material or feedstock is collected and placed into either a furnace or crucible. 2.) Polysilicon is produced either by the Siemens chemical vapor deposition process in a reactor furnace to produce rods, or via the fluid bed reactor process to produce granules; whereas Monocrystalline ingots are produced using higher purity semiconductor-grade silicon via the Czochralski process whereby a seed crystal is pulled from an inert quartz crucible. 3.) Shows the output of single crystalline silicon ingot. 4.) Describes the shaping of an ingot. 5.) Is the shaping result of a silicon ingot with tops and tails removed. 6.) Slices the silicon ingot into a wafer. 7.) Edge rounding of the wafer. 8.) Wafer lapping removes bulk silicon from wafer. 9.) Wafer etching process to clean silicon wafer. 10.) Wafer polishing evens out wafer topography. 11.) Is the final wafer cleaning which removes any remaining contaminants. 12.) Inspects the finished wafer for any irregularities. 13.) Finished wafers are packed for shipping. 14.) Product shipped to end user